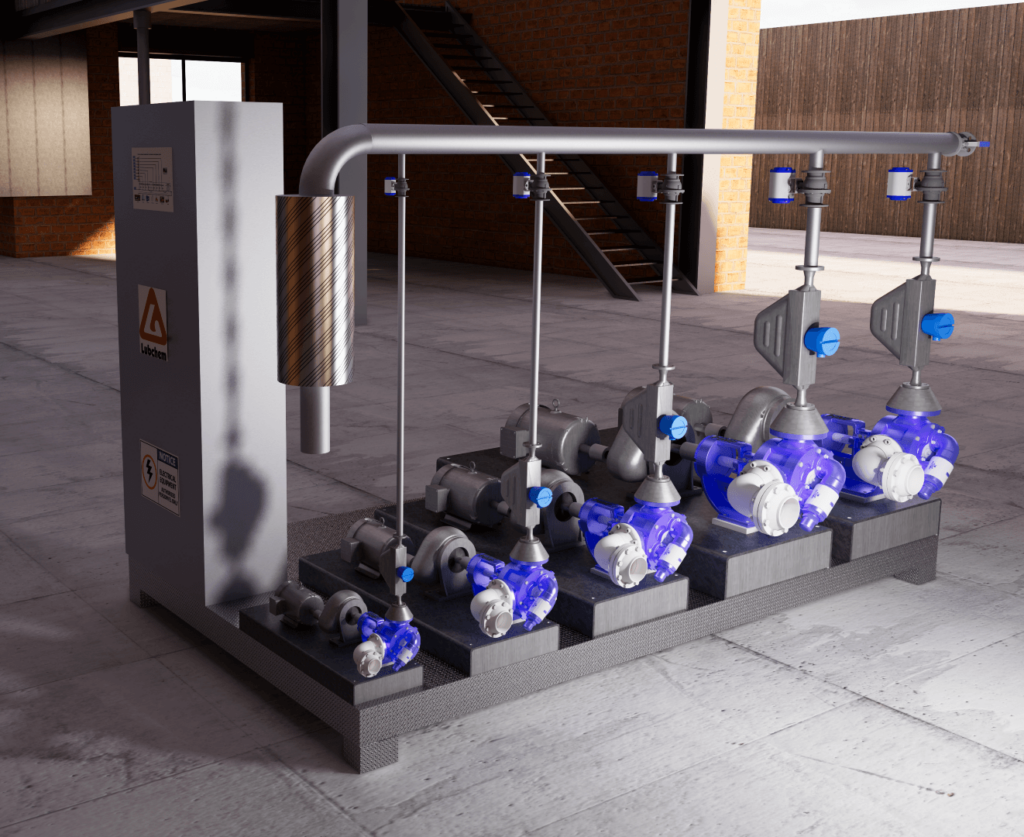

Continuous On-Demand Liquid Blending

Revolutionize your liquid mixing process with AccuBlend’s state-of-the-art, modular, on-demand continuous inline liquid blending and formulation system. Say goodbye to time-consuming tank cleaning, wastewater treatment costs, and excessive tankage and storage requirements. Experience the seamless transformation between product variants with our innovative liquid blending solutions.

The benefits of our liquid blending process include:

- Spend more time producing product and less time washing out between changeovers to the next product family variant.

- Spend less capital than a batching system of equal output will cost.

- Formulate more consistent product by achieving higher dosing accuracy through the use of Coriolis mass flow measurement technology.

- Minimize washout effluent volumes and associated treatment costs.

- Reduce inventory carrying cost due to ease and flexibility of rapid changeover.

- Reduce ingredient raw material cost by minimizing washout volumes and extremely accurate dosing.

- Reduce staffing via fully automated and self-policing blending system operation.

- Save valuable floor space due to less tankage and compact, modular design.

- Allow ease of future relocation to another part of the plant or an entirely different location as a result of modular design.

- Don’t let batch mixing hold you back! Let AccuBlend Inline optimize your liquid formulation process with our cutting-edge liquid blending and formulation solutions. Contact us today to learn more about how we can revolutionize your manufacturing capabilities.