Configuring Your System

“Know Your +/-5% Price

On the Initial Consultation Call”

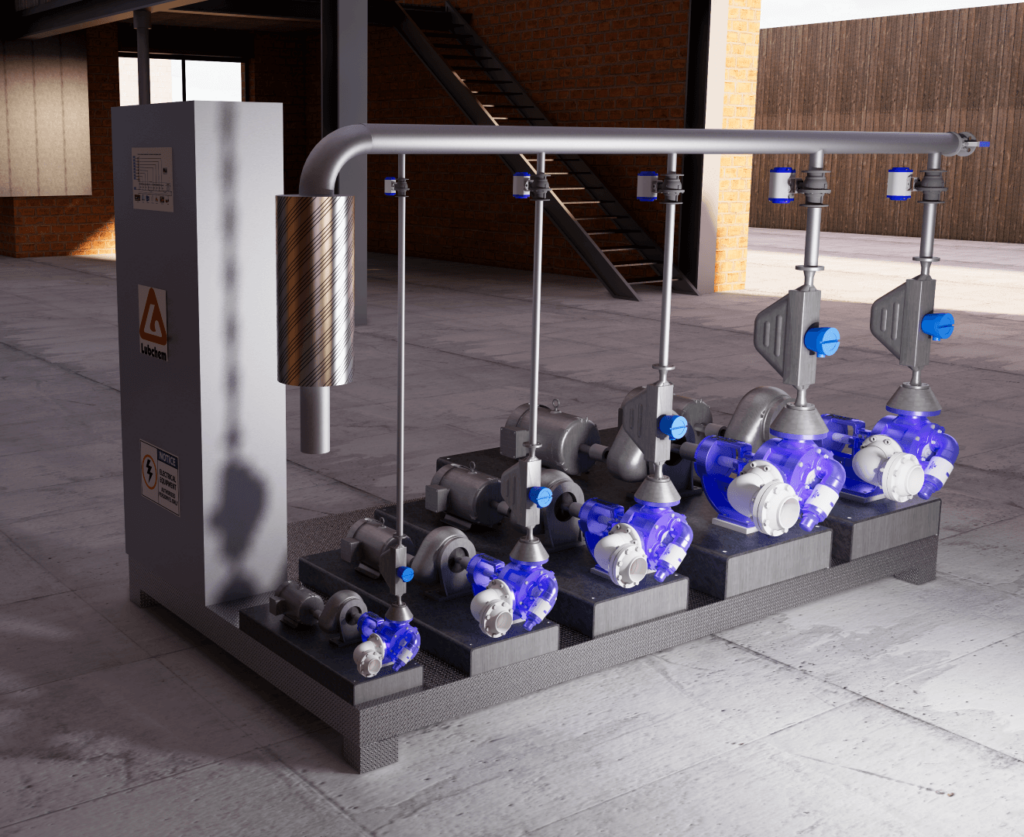

Maximize your production quality and efficiency with our state-of-the-art liquid blending systems. Our team of experts will help you configure the perfect solution tailored to your unique needs.

Configuring Your System

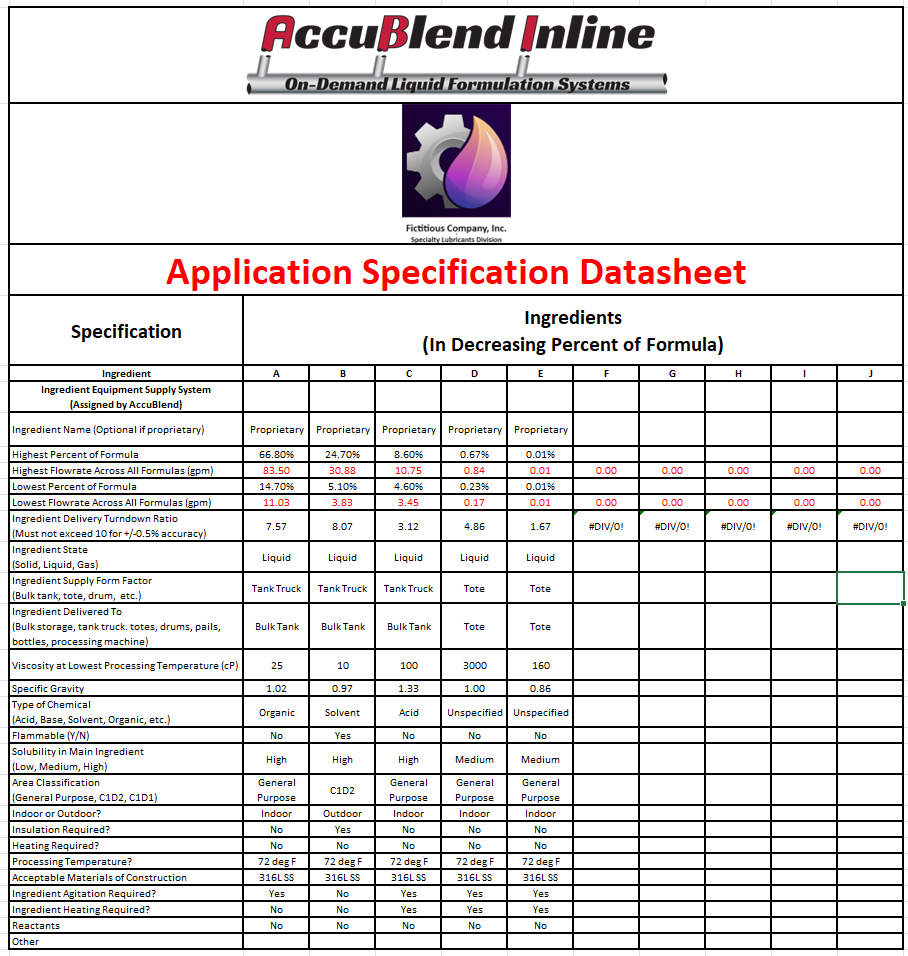

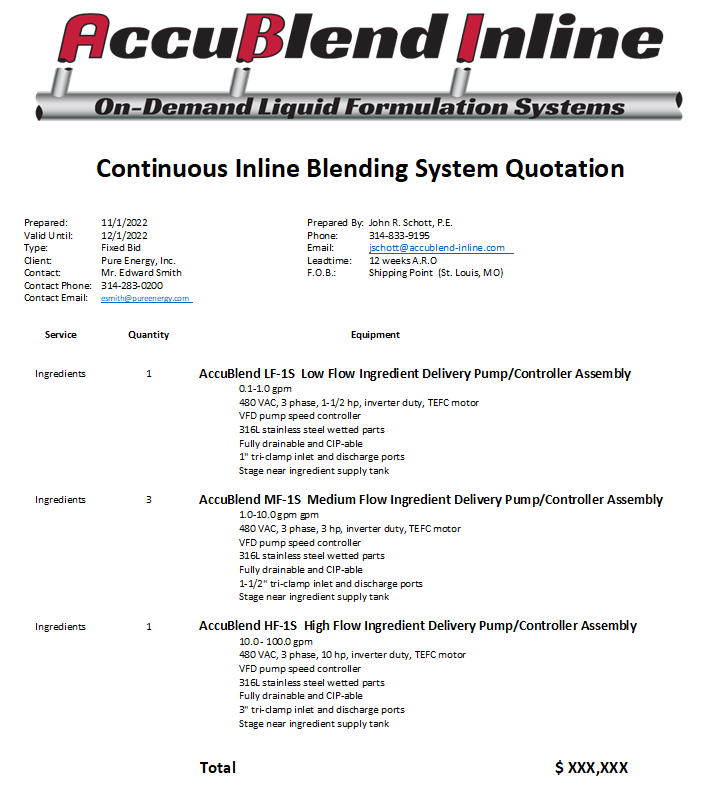

Your system can be configured during the first consultation call. It’s as simple as determining a maximum finished product flow rate and the maximum formula percentages of each unique ingredients across all recipes that will be run.

This intuitive liquid mixing calculation process allows us to provide you with the most effective and efficient liquid blending solution for your needs.

Once your system configuration is complete, we can immediately generate a fixed bid price for the entire liquid blending system. This liquid blending quote ensures transparency and allows you to effectively budget for the future of your operation.

A +/- 5% price can be immediately generated once system configuration is complete.

Whether you’re in the food and beverage industry, consumer products, industrial materials, or petrochemicals, our fully customized liquid blending systems will streamline your production process, delivering a significant return on investment.

Don’t delay; contact us today to schedule your first consultation call, and let’s start optimizing your liquid blending operations!

Minor Ingredient Supply Strategy

We recommend what is known in the industry as a “Mother/Daughter” ingredient storage/supply system for all ingredients that are a small percentage of your recipes.

The Mother tote is sized to be 20% larger in volume than the ingredient totes you receive from your suppliers. This allows for continuous operation of the inline blending system while ingredients are replenished.

When the Mother tote reaches a level of 15%, the operator will be notified. At this point, the operator can open the Daughter tote discharge valve. Then gravity takes over to replenish the Mother tote, resulting in no need to stop the blending system for ingredient replenishment!

After the Daughter tote is fully drained into the Mother tote, you simply remove the empty Daughter tote and pallet with a forklift and place a new Daughter ingredient tote on top of the Mother tote. Repeat as required, based upon ingredient usage rates.